Design engineers and inventors need to come up with new a lighting technology which is energy-saving and cost effective. LED light-curing technology is the latest technology which is going to be both. This technology is going to render users with both quality and energy saving. Many medical device manufacturing industry are going for LED for various reasons.

Soon, UV light-curing technology is going to be replaced by LED light-curing technology applied in medical technology assembly. Simply, because of the reason that LED technology has energy and manufacturing advantages. Conventional lamps need higher temperatures compared to LED light curing equipment in order to get a full cure. This makes the implementation of LED light as advantageous.

Cooler curing temperature are useful in obtaining better thermal management rendered possible by the use of LED curing equipment’s narrow wavelength spectrum emission. Eventually, this results in led thermal rise and is considered integral in preserving the hat sensitive substrates.

Due, to less transition and fluctuations in the temperature the LED curing equipment are able to maintain stable intensity. In the end, this makes it possible for manufactures to improve process controls with uniform curing which gives reliable results.

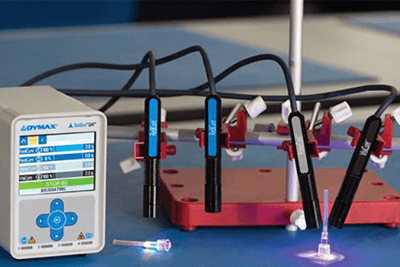

The maintenance and replacement of the bulb is tremendously reduced by the use of LED–curing equipment. As no bulbs need to be changed the equipment offers 20,000 hours of reliable use. An example of this technology is the BlueWave QX4, which is unique in the fact that each of the four LED heads can be a different wavelength and controlled independently.

This means getting four spot-cure systems in one. Its application is ideal for ideal for products that need to be bonded in multiple places using adhesives that cure at various wavelengths. This will not only save energy but also save space when the manufacturers are doing pre-production testing.

The other feature which makes it better is that it uses LED wands. The LED is located in the wand which makes it feasible for efficient delivery of curing energy. LED wands deliver curing energy specifically to bond areas. Users can also add wand cable extensions whenever required in order to deliver the curing energy at further distances with specificity.