Predictable arrays of plasmonic nano-particles can be generated on the surface of LEDs to improve photon emission by localised surface plasmon resonances according to the research carried out at the University of Michigan. “The idea of adding nano-particles to increase LED efficiency is not new, but previous efforts to incorporate them have been impractical for large-scale manufacturing,” said the University.

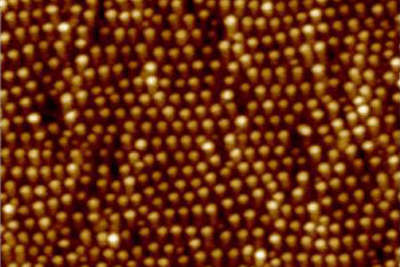

“They focused on pricey metals like silver, gold and platinum. Furthermore, there was no cost-effective way to incorporate particles below the surface.” The research carried on made the use of gallium arsenide, irradiating its surface with a focused beam of gallium ions. Self- assembling arrays of same sized Gallium particles grew along with other things and the beam angle with respect to the substrate controlled the population density and the particle size.

Different combinations of particle size and burial layer thickness were tried, with the emissive characteristics measured by photo-luminescence. “If you carefully tailor the size and spacing of nano-particles and how deeply they’re embedded, you can find a sweet spot that enhances light emissions,” said researcher Myungkoo Kang.

The university stated, that similar occurrences happened before in which formation of metallic particles on semiconductors were seen generally as a nuisance during chip making when process control was not that efficient. “We realised that those ‘mistakes’ are very similar to the particles that manufacturers have been trying so hard to incorporate into LEDs. So we figured out a way to make lemonade out of lemons,” said project leader Professor Rachel Goldman.

It has been reported previously that Gallium can produce plasmon responses tunable from near infra-red to ultra-violet. The researchers at the University are adapting its technique, the gallium nitride used in lighting LED’s where it could help increase the efficiency of LED lighting by 50%.